Precision Metrology Lab for Centrifugal Compressors

At Air Relief, our state-of-the-art Metrology Lab is dedicated to ensuring the optimal performance and precision of your centrifugal compressors. Equipped with cutting-edge measurement technology and backed by a team of highly skilled engineers, our lab plays a crucial role in both repairing and remanufacturing critical compressor components such as impellers and diffusers. We provide highly accurate measurements that enable precise part replication, ensuring your compressor systems operate efficiently, reliably, and for a longer lifespan.

Why Choose Air Relief’s Metrology Lab?

High-Precision Measurements

Ensure the integrity of your compressor parts with exact measurements

Extended Equipment Lifespan

Accurately designed parts promote long-lasting performance.

Increased Operational Efficiency

Precisely captured components reduce operational disruptions and energy costs.

Customized Impeller and Diffuser Configurations

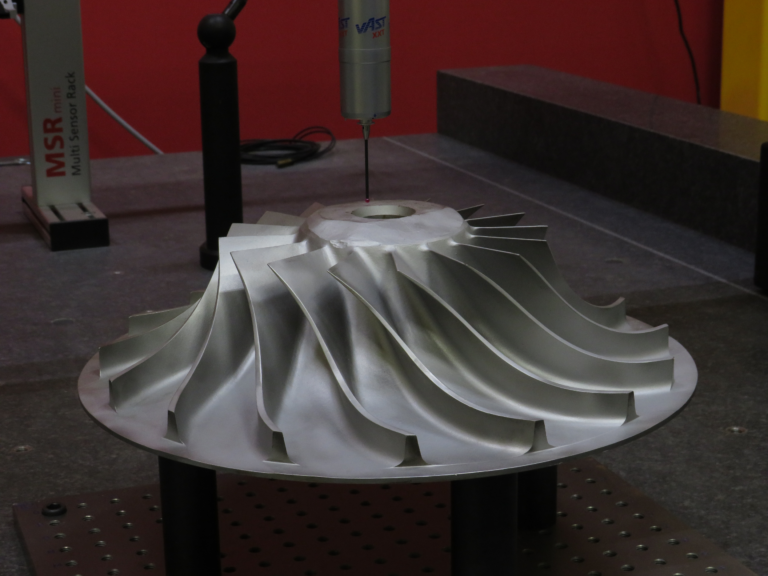

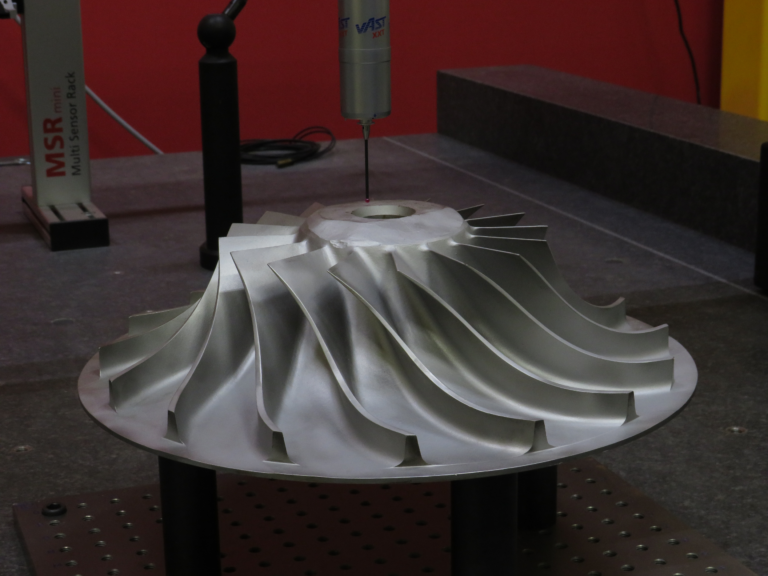

Each centrifugal compressor has unique impeller and diffuser configurations, modified during its original manufacturing to suit the specific needs of the customer’s site. To assist with repairs and remanufacturing, we build libraries of these configurations, capturing the exact shapes and dimensions. Our Metrology Lab utilizes specialized tools and software to document and replicate these complex parts.

- Custom Configurations: Capture and document unique compressor component shapes.

- Repair & Remanufacturing: Rebuild components to meet original specifications, improving performance.

Specialized Tools & Software

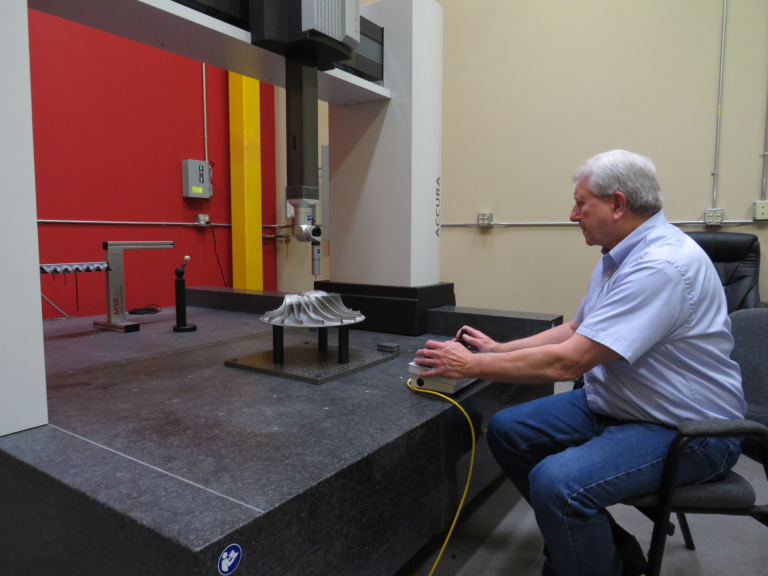

At the core of our Metrology Lab lies a suite of advanced measurement tools and software designed to deliver highly accurate results for every compressor part we handle:

- Zeiss Coordinate Measurement Machine: Offers precision measurements for the most intricate components.

- FARO Measurement Arm: Captures 3D data for complex geometric shapes like impeller blades and diffuser vanes.

- Laser Scanning: Provides detailed imaging of components, ensuring accurate data collection and modeling.

We combine these high-precision tools with specialized software to process the data and create detailed models of your compressor parts.

Beyond Data Collection: Precision Engineering

While many companies capture raw data, Air Relief takes it further. Our team not only collects the data but also processes it using advanced engineering software to transform raw data into serviceable models. This ensures we deliver parts with the highest accuracy, providing comprehensive solutions that go beyond data capture.

- Engineering Expertise: Translate raw data into precise, functional compressor models.

- Comprehensive Solutions: Provide complete, accurate part models to improve compressor efficiency.

Frequently Asked Questions (FAQ)

Metrology is crucial because precise measurements lead to more accurate repairs and remanufacturing of compressor parts. Accurate data helps ensure optimal performance, reduces energy consumption, and extends the lifespan of your equipment.

Our Metrology Lab captures the exact configuration of your compressor parts, including impellers and diffusers, and builds detailed libraries of these unique shapes and dimensions. This allows us to efficiently repair or remanufacture components to original specifications, ensuring your compressor operates at peak efficiency.

We utilize cutting-edge measurement tools such as the Zeiss coordinate measurement machine, FARO measurement arm, and laser scanners. These tools enable us to capture high-precision data from complex components like impeller blades and diffuser vanes.

Contact Us for Expert Metrology Services

Looking to optimize the performance of your centrifugal compressors? Air Relief’s Metrology Lab provides the precise measurements, expert engineering, and custom solutions you need. Contact us today to learn how we can help maintain and improve the efficiency of your equipment.