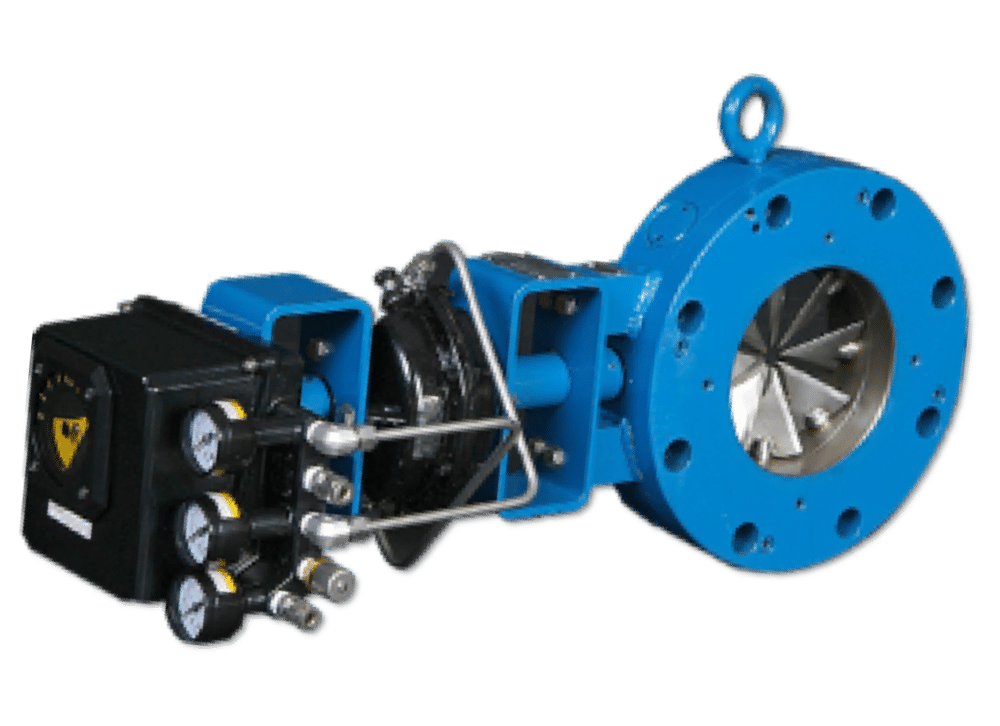

Inlet Guide Vane

Save Energy and Reduce Maintenance Cost

Control valves for a centrifugal air compressor include the butterfly, inlet, and check/safety vanes. But, inlet guide vanes/ inlet valves provide a cost-effective way to save energy and reduce maintenance costs.

We stand behind our services and components 100% and ensure our products and your machines will operate optimally together.

Benefits of an Inlet Guide Vane

- The internals are factory-lubed and sealed to prevent debris from entering the vanes

- Our stainless steel vanes eliminate corrosion

- It provides a tighter, more controlled system

- The thin-line style is only 2 inches wide

- Our products are priced competitively

Cost Saving Benefits

- When inlet guide vanes are throttled, the pre-swirl air entering the eye of the first stage impeller reduces the amount of horsepower and can increase energy savings (CFM per kW)

- Gear-driven over linkage-driven valves provide smoother control and lowers the routine maintenance costs

- In full-throttled mode, inlet guide vanes lower the amperes consumption by an average of 3 to 7% compared to a butterfly valve

- The return on investment (ROI) can be as little as one year, depending on the location and the specific energy costs

Recommended Maintenance

The Air Relief gear synchronized inlet guide vane is constructed and designed for minimum maintenance for our customers. However, some routine upkeep is required to keep your air compressor working at the optimal level. Remember when replacing or repairing parts, match components, and put reassembled parts back in the original positions.

Every 2 Years:

- Replace the lead disc

- Replace the wire shear indicator

- Replace the coupling to main vane stem spring pin

Every 5 Years:

- Remove the valve and the joint face gasket material and its cover. Take out the old lubricant, clean the valve, and then add new lubricant

- Inspect vanes and stems for fatigue cracks

- Check for excessive looseness in brass vane stems bearings (plain and thrust) and replace, if needed

- Inspect the main drive pinion for excessive wear. If the pinion needs to be replaced, the entire vane will also need to be replaced

- Before reassembling the actuator to the valve, check for smooth operation. It’s normal for the assembly to take slightly more effort to overcome the drag of the “O” rings

During the preventative maintenance process, if you have any questions or need additional assistance, give us a call. The benefit of our many years of experience is available to you 24/7/365.